The Future of Replicators: Making Your Desires Materialize

Written on

Chapter 1: Introduction to Replicators

Imagine waking up one morning craving a bagel, only to realize you forgot to buy any. Fortunately, you have a replicator at your disposal. This compact device, similar in size to a toaster oven or printer, can produce any item you desire. With a few quick commands, it springs into action, and soon, a freshly baked bagel appears on your plate.

This concept may seem like a distant fantasy, but advancements in technology have brought us closer to this reality than we might think. The ability to conjure up desired items on demand is truly remarkable, and we are already seeing the initial stages of this capability through current devices. Let’s examine the broader technological landscape, beginning with the 3D printers that many have access to today.

Section 1.1: The Role of 3D Printing

Individuals who own a 3D printer can create almost any solid object within its build area. While the materials used can differ, typically, only one type is utilized per machine—unless in specialized industrial settings. The dream of replicating items is gradually coming to fruition, especially with non-perishable goods like food. A 3D printer operates by receiving commands from a computer, converting them into a physical object. This process may not be the simplest, but it is straightforward enough for users to provide the necessary instructions.

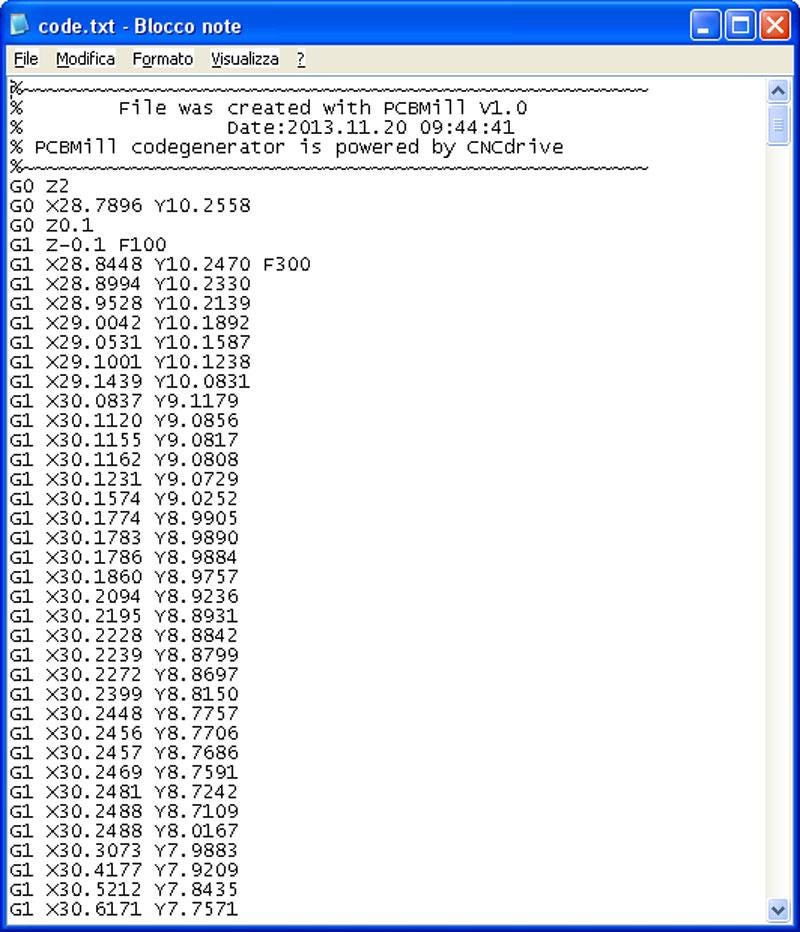

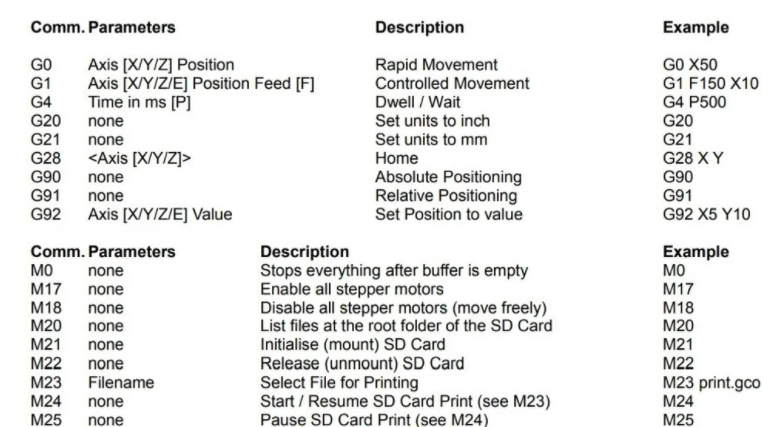

This programming is executed in a language called G-code, which consists of specific instructions detailing the printer's movements and extrusion timing. Although G-code can appear complex, it comprises a series of basic commands that simplify its understanding. When you design a three-dimensional model using CAD software and connect it to the printer, a program translates your design into G-code. If you wish to modify these actions, you will need to manually adjust the G-code for the desired outcome.

By applying various commands to alter the output, you can successfully customize the 3D printing process. Regardless of what you envision in the CAD design, G-code allows you to manipulate the outcome, enabling you to create your desired items.

The sizes of these printers vary significantly. Some are capable of constructing entire structures, while others are portable enough to carry around. However, a key limitation is that we still require printing materials, as complete replication is not yet achievable.

Section 1.2: 3D Printing Food

Having established that we can 3D print objects, why not extend this technology to food? The primary challenge lies in the methodology. Conventional 3D printers cannot apply the same principles to food items. For instance, unlike plastic, which can be heated and quickly cooled to maintain shape, food ingredients behave differently.

However, researchers are exploring ways to use 3D printers for edible creations. One example involves extruding pancake batter onto a heated surface to produce pancakes. The key is that any food item can be printed as long as its ingredients can be pureed to fit through a nozzle.

Instead of using the typical spools associated with various 3D printing materials, food ingredients need to be contained in a specialized metal syringe approved for food use. The concept of 3D printed food is already a reality in some urban restaurants, provided you have a dedicated food 3D printer that is kept clean.

Returning to the bagel scenario, although you may not be able to print one due to the inability to puree the dough, you can still create other puree-able snacks. While fully replicating any item may take time, there’s no reason not to start experimenting with various foods.

Chapter 2: The Future of Replicators

In this video titled "How Far Away Are We From Replicators?", we delve into the advancements and challenges in the development of replicator technology.

The next video, "Atomic Replicators: The Future of 3D Printing", explores the potential of atomic replicators and their implications for the future of 3D printing.

Thank you for engaging with this article! If you’d like to discuss further, feel free to reach out to me at [email protected] or connect with me on LinkedIn under Amelia Settembre.